Overhead Crane

metallurgy Foundry Overhead Crane

If you want buy this product,You can contact us via the contact details below

Metallurgy Foundry Overhead Crane also can be called Casting Overhead Crane, and it usually is double girder overhead crane.

Metallurgy Foundry Overhead Crane is mainly used in BOF, EAF and CCP bays in steel smelting shop for molten metal lifting, lifting capacity is from 5T to 160/40T, working duty of the complete machine is A7.

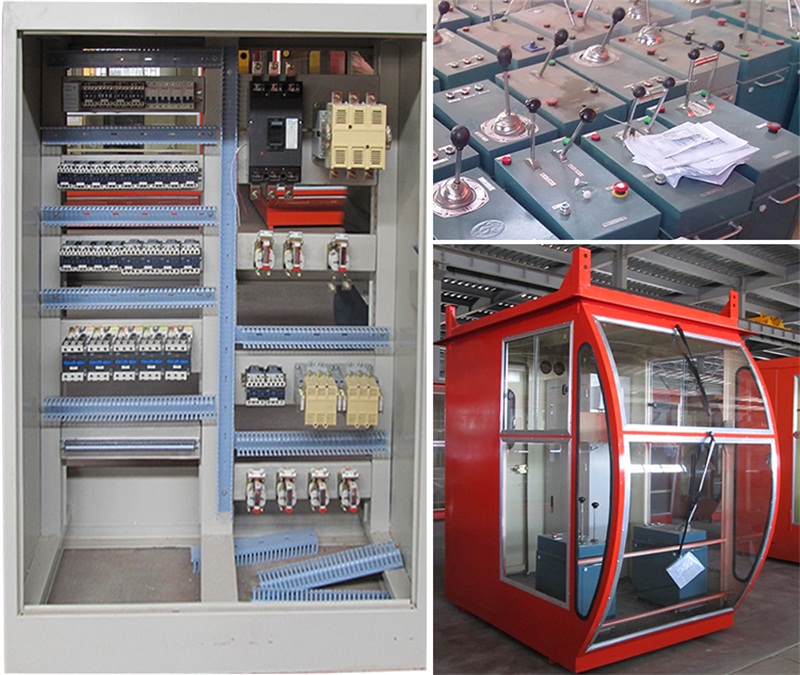

Just like common double girder overhead crane, there are four beams (double main beam and two end beam) and two trolleys, with thermal-protective coating is added at the bottom of the main girder, laminated ladle hook is equipped on the main trolley for lifting the ladle, and aux trolley is for overturning the ladle and other assistant handling.

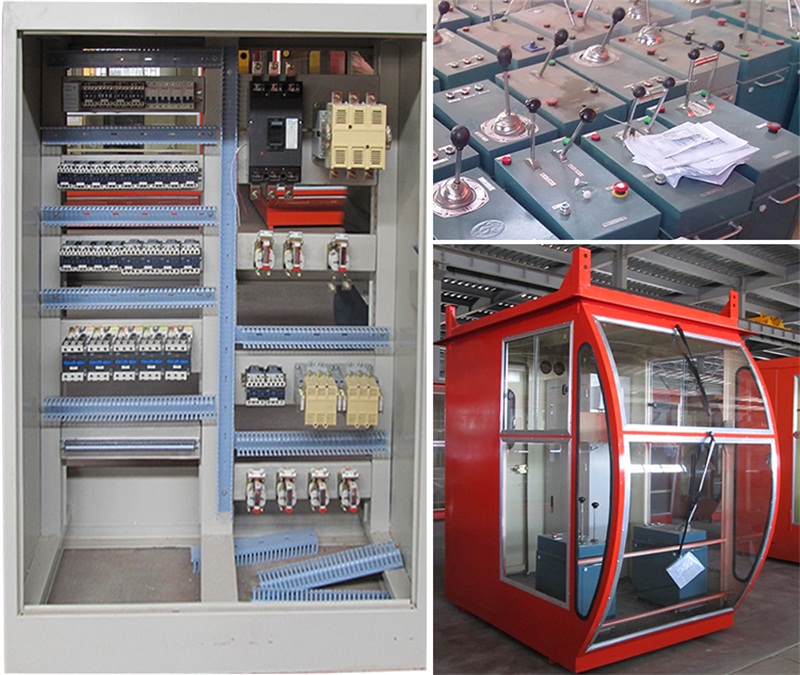

The Metallurgy Foundry Overhead Crane electrical appliance is installed inside of the main girder with heat insulation device and cooling device, the crane can work efficiently under harsh conditions such as high temperature and dust-laden.

Metallurgy Foundry Overhead Crane Feature

|

|

|

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metallurgy Foundry Overhead Crane Feature

1. Assembling and test of the crane conform to the document no. ZJBT (2007)375 which was issued by general administration of quality supervisor, inspection and quarantine of the people's republic of China

2. The place where molten nonmetal material and red-hot solid metal is lifted also can refer to this document.

3. With advanced welding technology, the toughness and strength are perfect combination in the main girder and end carriages

4. Electric equipment is installed in the girder, and the girder's electric panel room with an air cooler employs rock wool for heat insulation

5. To reduce the radiation of molten steel, the thermal-protective coating is added at the bottom of the main girder

6. Motor: H class, IP55 is better design than QD

7. Electric cable and electric appliances with high-temperature resistance

8. Double-brake guarantees high safety

9. Steel-core wire rope makes itself more strength and toughness

Metallurgy Foundry Overhead Crane Safety Protection

* Overload protection

* Long and cross travel limit

* Anti-falling protection

* Emergency stop switch:

* Polyurethane buffer

* Safety hook latch

* Audible and visual alarm device

* Protective earth conductor

* Voltage lower protection

* Current overload protection system

Please leave your message,We will contact you soon!